- Overview

- Product Description

Basic Info.

Model NO.

WF-JF

Usage

Electrical Appliance

Material

Steel

Type

U Type

Item

Cable Clamp

Export Markets

Global

Shipping Port

Qingdao

Place of Origin

China

Transport

by Sea or Air

Packing

Wooden Cases or Carton

Weight

Customized

Sample

7 Days Ready

Processing

as Per Your Drawing

Materials

as Per Request

After-Sale Service

Definetly

Certificate of Origin

as Per Request

Transport Package

Plywood Box

Specification

As your requirement

Trademark

jufeng

Origin

Weifang City, Shandong Province, China

HS Code

7326199000

Production Capacity

100000PCS/Month

Packaging & Delivery

Package Size

40.00cm * 30.00cm * 20.00cm

Package Gross Weight

50.000kg

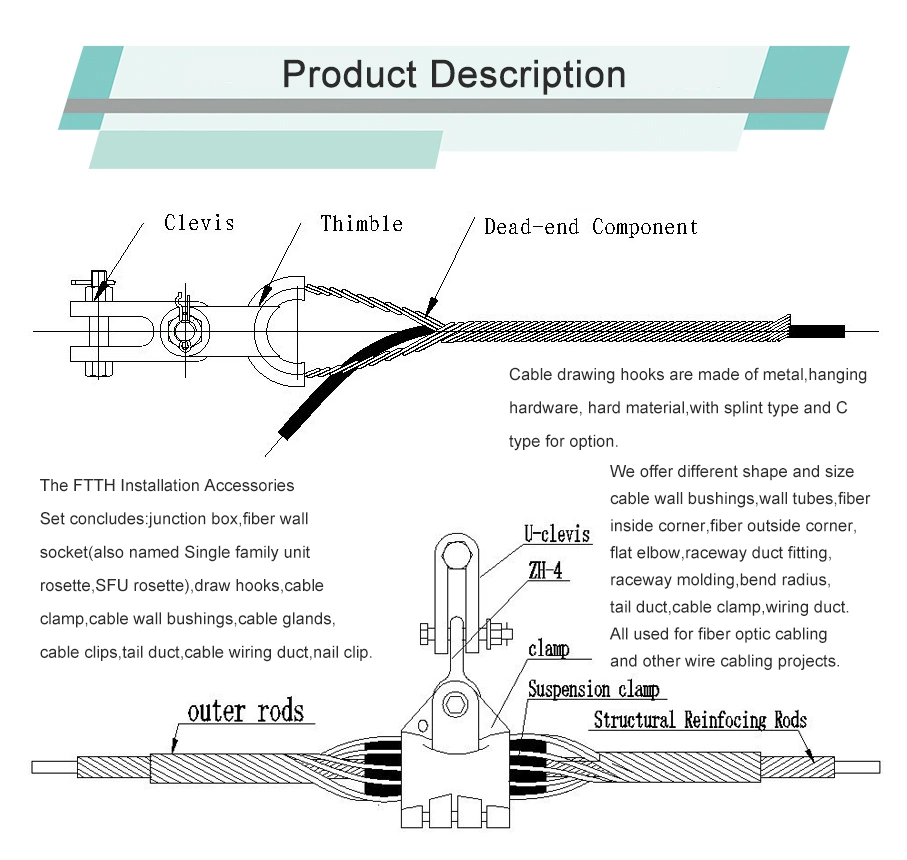

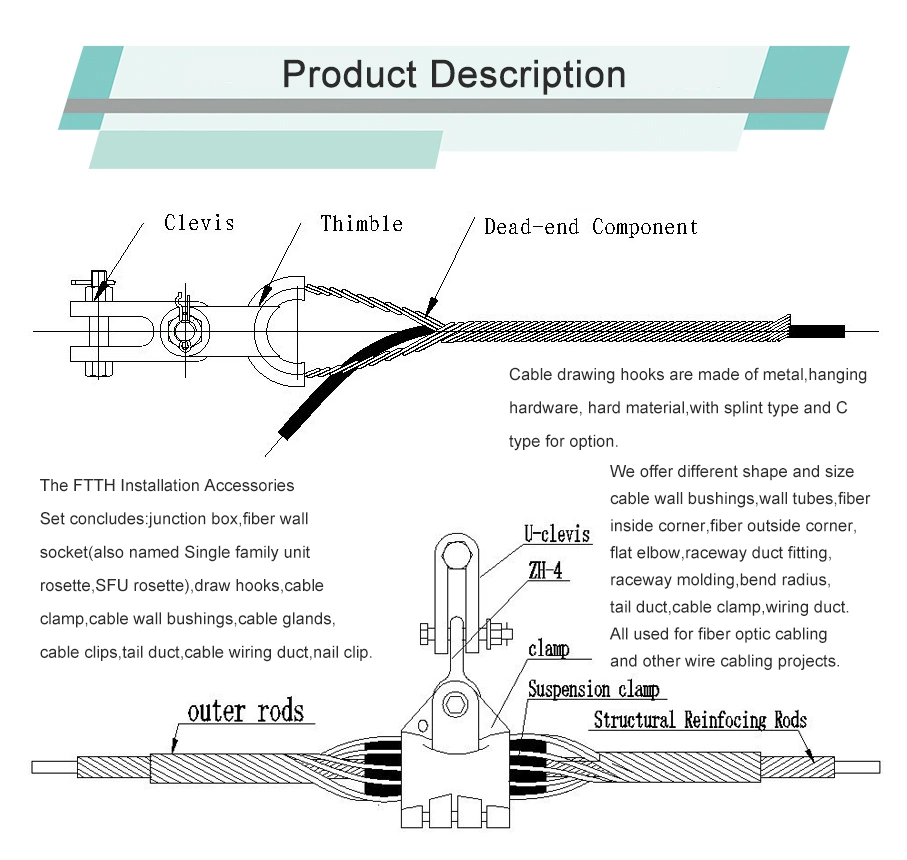

Product Description

ADSS Fiber Optic Cable / Electric Pole Fittings Metal Rubber Down Lead Clamp

The lead-down clamp is used to lead down the optical cable and fix the optical cable when it is jumpered, which improves the mechanical performance of the clamp. It is mainly used for the communication line of the newly built overhead high-voltage power transmission system of 35kv and above. The stainless steel tube and cable core stranding design is reasonable, and the optical fiber is redundant. The length is accurate; the all-dielectric self-supporting optical cable (adss) is suspended on the pole tower with the line turning angle less than 25°.

Main products:

FTTH optical fiber home accessories, optical cable communication iron parts, FTTH butterfly-shaped optical

cable accessories, s-type fixing parts, clamp hooks, cable clamps, c-type hooks, splint hooks, clamp hooks,

ring hooks, steel With hoop, optical cable reserve rack, turnbuckle, FTTH injection molding accessories, and customized special-shaped products, etc.

Product details:

Down-lead clamps for rubber towers are used to fix the up and down or up of the optical cable on the tower so

that it will not shake and avoid the optical cable from wearing.

Features:

Features:

1.Wide range of application: It is suitable for skeleton type, layer stranded type, beam tube type armored and non-armored fiber optic cables, and is flexible in use.

2. Dielectric strength: 15kv DC, no breakdown in 2 minutes.

3.Function of the down-lead clamp for the stainless steel belt-shaped pole: fasten the optical cable that is drawn down or up from the pole to the pole so that it cannot be shaken, so as to avoid the abrasion of the optical cable.

4.Conditions: the first and end poles, connecting poles, etc. of the optical cable line.

5.Usage: Generally install one every 1.5 meters.

OUR PRODUCING PROCESS:

1. Tooling (Mold) design and Manufacture.

2. Manufacture the parts according to the Stamping Machine.

3. Riveting, Welding or Screw tap according to Customer's require.

4. After finish manufacture process we will test the parts by the Image measurement instrument, Caliper,

Angel Gage etc.

5. After make sure all the dimension can reach customer's require, we will make the surface treatment process.

6. After finish surface treatment we will testing all the parts by worker so that we can make sure the parts which

we sell is 100% qualified.

7. After finish testing we will pack the parts by Vacuum Package Machine.

Quality control:

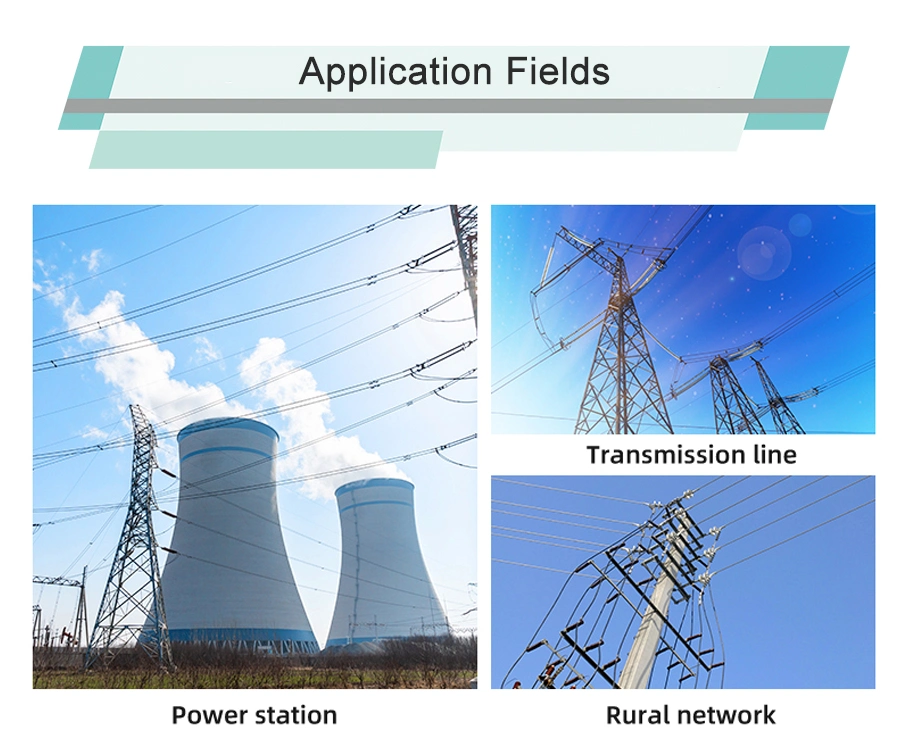

The products are widely used in transmission and distribution lines of electrical energy, optical cable lines and

high-speed railway lines.The lead-down clamp is used to lead down the optical cable and fix the optical cable when it is jumpered, which improves the mechanical performance of the clamp. It is mainly used for the communication line of the newly built overhead high-voltage power transmission system of 35kv and above. The stainless steel tube and cable core stranding design is reasonable, and the optical fiber is redundant. The length is accurate; the all-dielectric self-supporting optical cable (adss) is suspended on the pole tower with the line turning angle less than 25°.

Main products:

FTTH optical fiber home accessories, optical cable communication iron parts, FTTH butterfly-shaped optical

cable accessories, s-type fixing parts, clamp hooks, cable clamps, c-type hooks, splint hooks, clamp hooks,

ring hooks, steel With hoop, optical cable reserve rack, turnbuckle, FTTH injection molding accessories, and customized special-shaped products, etc.

Product details:

Down-lead clamps for rubber towers are used to fix the up and down or up of the optical cable on the tower so

that it will not shake and avoid the optical cable from wearing.

| Product Name | Model | Conductor dia(mm) | Remark |

| Rubber download clamp for tower | TGY 1110-T | 9.0-11.1 | ADSS |

| TGY 1330-T | 11.2-13.3 | ||

| TGY 1550-T | 13.4-15.5 | ||

| TGY 1800-T | 15.6-18.0 | ||

| Metal download clamp for pole | TGY 115-T | 7.0-11.5 | OPGW |

| TGY 160-T | 11.6-16.0 | ||

| TGY 200-T | 16.1-20.0 | ||

| Rubber download clamp for pole | TGY 1110-H* | 9.0-11.1 | ADSS |

| TGY 1330-H* | 11.2-13.3 | ||

| TGY 1550-H* | 13.4-15.5 | ||

| TGY 1800-H* | 15.6-18.0 | ||

| Metal download clamp for pole | TGY 115-H* | 7.0-11.5 | OPGW |

Features:

Features:1.Wide range of application: It is suitable for skeleton type, layer stranded type, beam tube type armored and non-armored fiber optic cables, and is flexible in use.

2. Dielectric strength: 15kv DC, no breakdown in 2 minutes.

3.Function of the down-lead clamp for the stainless steel belt-shaped pole: fasten the optical cable that is drawn down or up from the pole to the pole so that it cannot be shaken, so as to avoid the abrasion of the optical cable.

4.Conditions: the first and end poles, connecting poles, etc. of the optical cable line.

5.Usage: Generally install one every 1.5 meters.

OUR PRODUCING PROCESS:

1. Tooling (Mold) design and Manufacture.

2. Manufacture the parts according to the Stamping Machine.

3. Riveting, Welding or Screw tap according to Customer's require.

4. After finish manufacture process we will test the parts by the Image measurement instrument, Caliper,

Angel Gage etc.

5. After make sure all the dimension can reach customer's require, we will make the surface treatment process.

6. After finish surface treatment we will testing all the parts by worker so that we can make sure the parts which

we sell is 100% qualified.

7. After finish testing we will pack the parts by Vacuum Package Machine.