Basic Info.

Model NO.

GYXTW Optical Fiber Cable

Core

Multicore

Certification

RoHS, CE, ISO9001, Reach

Brand

OEM

Sheath Material

LSZH, HDPE, MDPE

Outer Sheath Color

Black ( Opitc Cable)

Max Number of Fiber

24 Fiber Optic Cable

Installation Style

Duct, Aerial

Jacket Material

MDPE /HDPE/ LSZH

Loose Tube Material

PBT Fiber Optic Cable

Waterblocking Material

Water Blocking Tape or Filling Compound

Armour Material

Corrugated Steel Tape

Stranding Member

Steel Wire or FRP

Temperature

-40degree--+60 Degree

Transport Package

Wooden Drum

Specification

2/4/8/12 Core

Trademark

TW-SCIE or OEM

Origin

Dongguan, Guangdong, China

HS Code

8544700000

Production Capacity

2000000kilometer/Year

Product Description

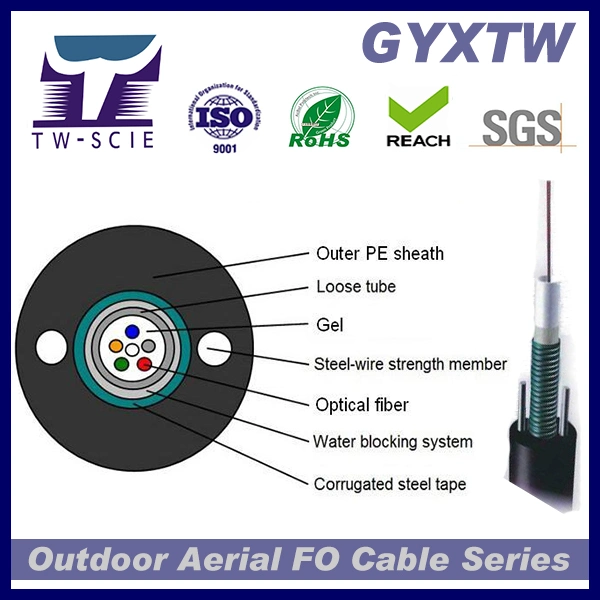

GYXTW Central Loose Tube Aerial/Duct Communication Optical Fiber Network Cable 4/8/12 Core

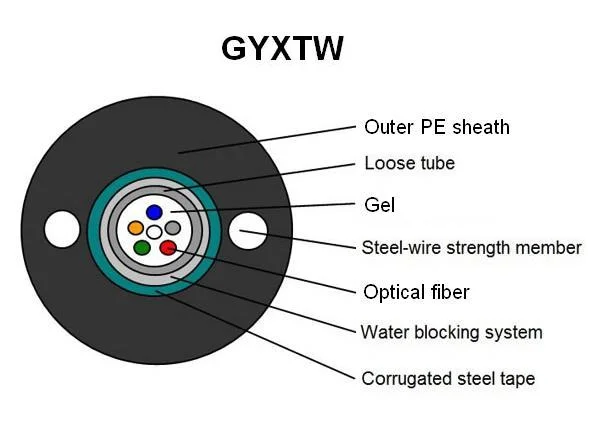

Description:

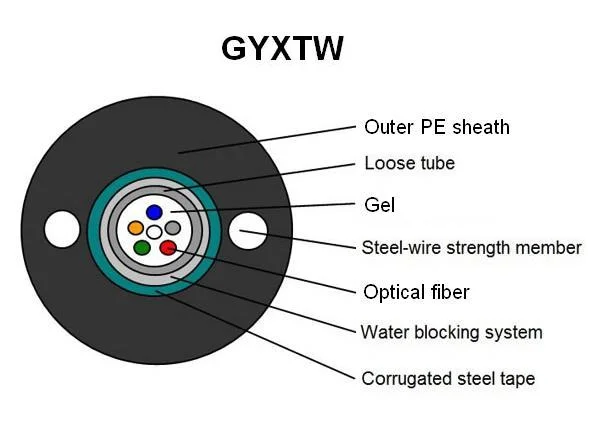

1. Single jelly compound filled loose tube containing up to 24 fibers

2. Waterproof tape between the steel tape and loose tube with jelly compound.

3. Double coated PE corrugated steel tape under PE sheath.

4. Parallel double steel wire as strength member.

5. Compact structure, light weight, steel tape armored excellent water-proof layer, good moisture.

General Specifications:

Fiber Specifications:

Cable Structure:

Cable Design:

Cable Performance:

More Pictures:

Company Overview:

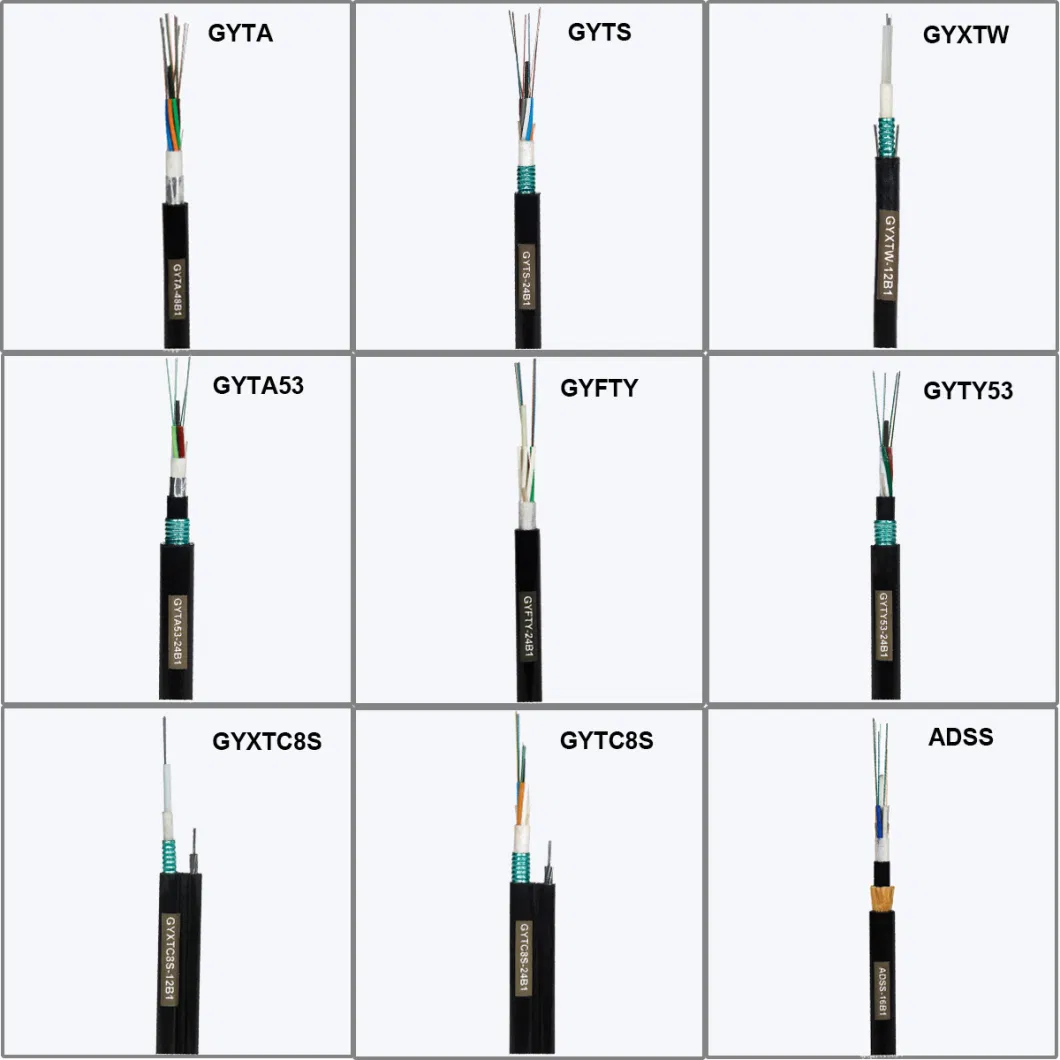

Related Products:

For more details please feel free to contact me. Any of your inquiry will reply within 24hrs.

Description:

1. Single jelly compound filled loose tube containing up to 24 fibers

2. Waterproof tape between the steel tape and loose tube with jelly compound.

3. Double coated PE corrugated steel tape under PE sheath.

4. Parallel double steel wire as strength member.

5. Compact structure, light weight, steel tape armored excellent water-proof layer, good moisture.

General Specifications:

| Cable Type | Central Loose Tube fiber optic cable GYXTW |

| Fiber Type | SM G.652D |

| Application | Long-distance communication, LAN |

| Recommended installation methods | Aerial |

| Environment | Outdoor |

| Temperature Range | -40ºC to 70ºC |

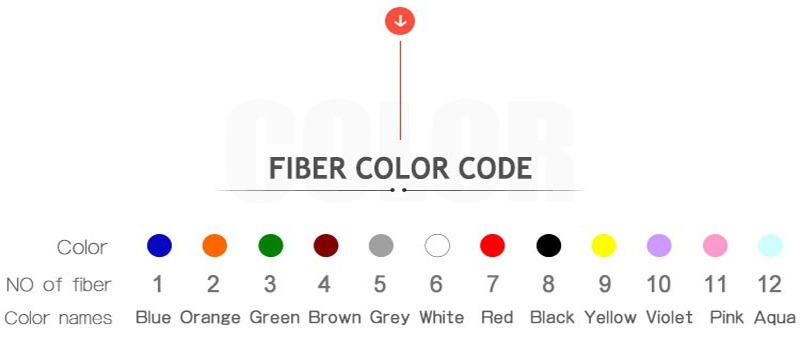

Fiber Specifications:

| Technical parameter of ITU-T G.652D (B1.3) single-mode optical fiber | |||

| Characteristics | Conditions | Specified Values | Units |

| Optical Characteristics | |||

| Mode field diameter (MFD) | 1310nm 1550nm | 9.2±0.4 10.4±0.8 | µm µm |

| Cut-off wavelength (λcc) | ≤1260 | nm | |

| Attenuation coefficient | 1310nm 1383nm 1550nm | <0.35 <0.35 <0.22 | dB/km dB/km dB/km |

| Macro bending loss | φ75mm, 100circles, at 1550nm | ≤0.1 | dB |

| Attenuation non-uniformity | ≤0.05 | dB | |

| Dispersion coefficient | 1288~1339nm 1271~1360nm 1550nm | ≤3.5 ≤5.3 ≤18 | Ps/(nm.km) Ps/(nm.km) Ps/(nm.km) |

| Zero dispersion wavelength | 1300~1324 | nm | |

| Max zero dispersion slope | ≤0.093 | Ps/(nm2.km) | |

| Group index of refraction (typical value) | 1310nm 1550nm | 1.466 1.467 | |

| Geometric characteristic | |||

| Cladding diameter | 125.0±1.0 | µm | |

| Core/cladding concentricity error | ≤0.8 | µm | |

| Cladding non-circularity | ≤1.0 | % | |

| Coating diameter | 245.0±10 | µm | |

| Cladding/coating concentricity error | ≤12.0 | µm | |

| Coating non-circularity | ≤8 | % | |

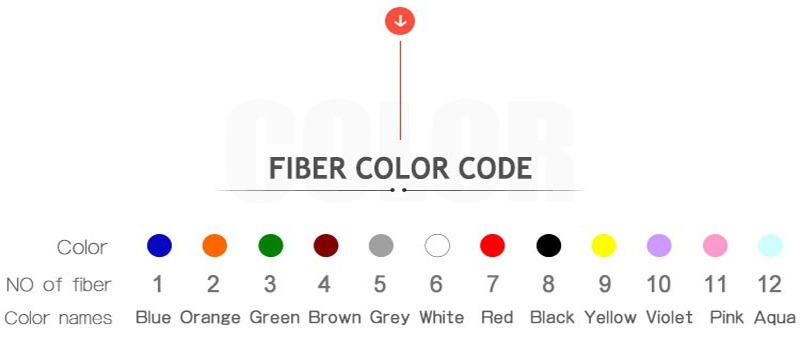

| Diameter of colored coating | 250.0±15 | µm | |

| Mechanical characteristic | |||

| Curling (radius) | ≥4 | m | |

| Proof stress | >0.69 | Gpa | |

| Coating strip force | Average value Peak value | 1.0-5.0 1.3-8.9 | N N |

| Dynamic stress corrosion susceptibility parameter (nd value) | ≥20 | ||

Cable Structure:

Cable Design:

| Item | Description | |

| Model No | GYXTW | |

| 1. Fiber count | 4-18 | 20-24 |

| 2. Cable Diameter | 7.4±0.2mm | 8.0±0.2mm |

| 3. Cable Weight | 56KG | 69KG |

| 4. Loose Tube | ||

| -Material | PBT | |

| -Outer diameter | 2.0 mm | 2.6mm |

| -Thickness | 0.3mm | |

| -Type of filling compound | Jelly | |

| 5.Strength member | ||

| -Material | Steel wire | |

| -Outer diameter | 1.0 mm | |

| -Number | 2 pcs | |

| 6.Armor | ||

| -Material | Corrugated steel tape | |

| 7. Water-blocking system | ||

| -Material | Filling Compound | |

| 8.Outer Sheath | ||

| -Material | HDPE | |

| -Thickness | 1.8mm±0.2mm | |

| 9. Sheath marking | ||

| -Type of marking | Laser printing | |

Cable Performance:

| Item | Testing | Test Method | Test Result |

| 1 | Tensile strength IEC 60794-1-E1 | Long-term:1500N Short-tern: 600N Cable length: ≥50m | Loss change≤0.1dB@1550nm No fiber break and no sheath damage |

| 2 | Impact IEC 60794-1-E4 | Height: 1m Weight: 1kg Impact spot: ≥5 Impact cycle: at lease 3 cycle per spot | Loss change≤0.1dB@1550nm No fiber break and no sheath damage |

| 3 | Repeated Bending IEC 60794-1-E6 | Bending diameter: 25X the cable outer diameter Applied load: 25kg Bending cycle: 30times Bending speed: 1 cycle per 2s | Loss change≤0.1dB@1550nm No fiber break and no sheath damage |

| 4 | Torsion IEC 60794-1-E7 | Torsion length: 1m Applied load: 25kg Torsion angle: ±90 or +180 Twist cycle: ≥10 times | Loss change≤0.1dB@1550nm No fiber break and no sheath damage |

| 5 | Water Penetration IEC 60794-1-F5B | Water height: 1m Cable length: 3m Keeping time: 24hours | No water leaked from the opposite end of cable |

| 6 | Temperature IEC 60794-1-F1 | Temperature step:+20°C->-40°C°C >+70°C->+20°C Keeping time: 24hours per each step Cycle:2times | Loss change≤0.1dB@1550nm No fiber break and no sheath damage |

| 7 | Compound flow IEC 60794-1-E14 | Sample length: 30cm Temperature: 70ºC±2ºC Keeping time: 24hours | No compound flow |

| 8 | Sheath high voltage test | On line test DC 12t kV(t-sheath thickness mm) | No sheath broken down |

More Pictures:

Company Overview:

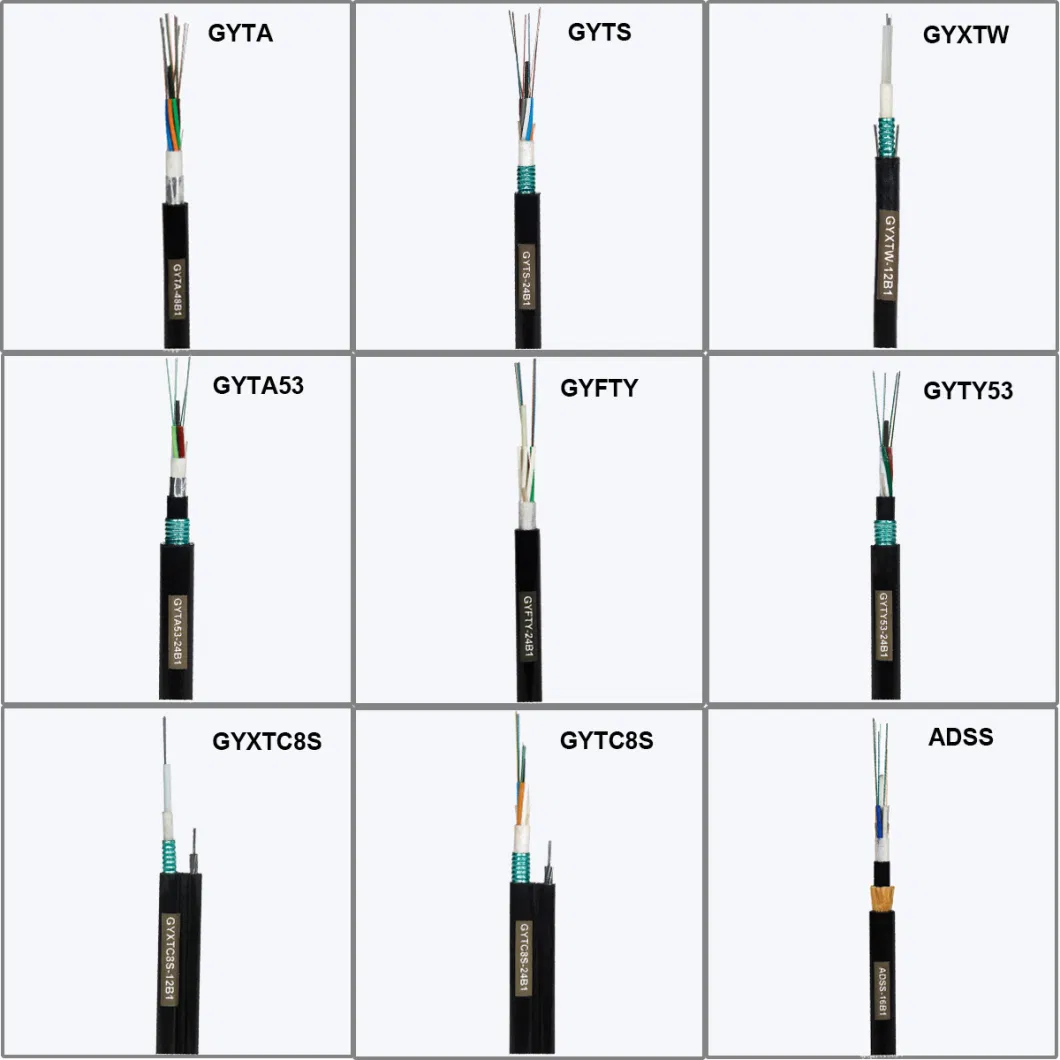

Related Products:

For more details please feel free to contact me. Any of your inquiry will reply within 24hrs.