Basic Info.

Model NO.

HLT

Pay-off Reel Size

236X25.4 X108mm

Fiber Pay-off Tension

0.5n-5n(Adjustable)

Extrusion Molding Machine

Sj65-25

Take-up Tension

5n-30n(Adjustable)

Take-up Reel Size

Pn280/Pn630

Center Height of Production Line

1000mm

Transport Package

Standard Seaworthy Package

Specification

ISO9001

Trademark

HLT

Origin

Jiangsu, China

HS Code

8477900000

Production Capacity

500 Sets Per Year

Product Description

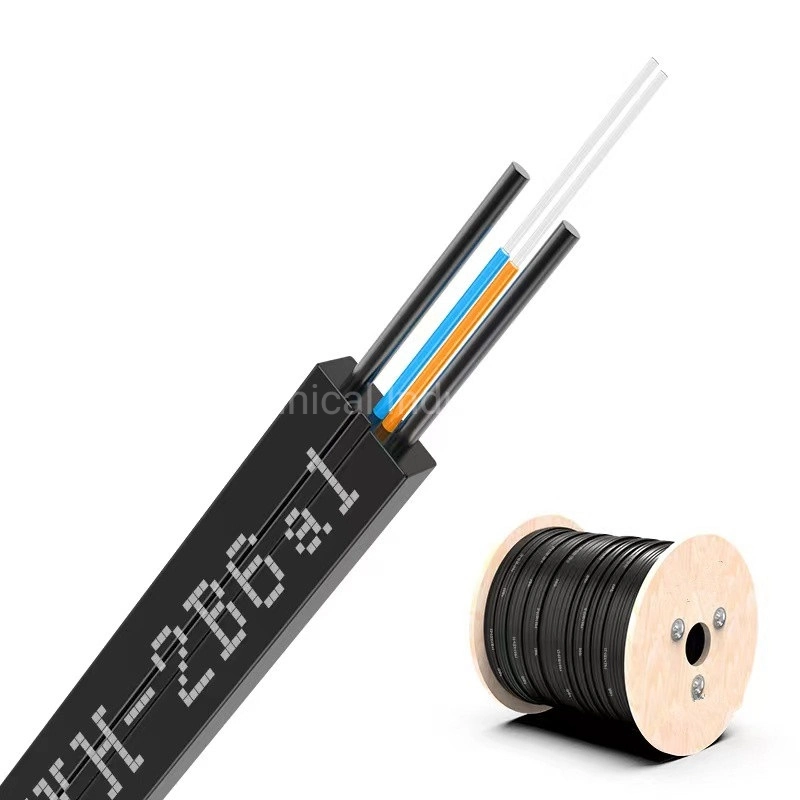

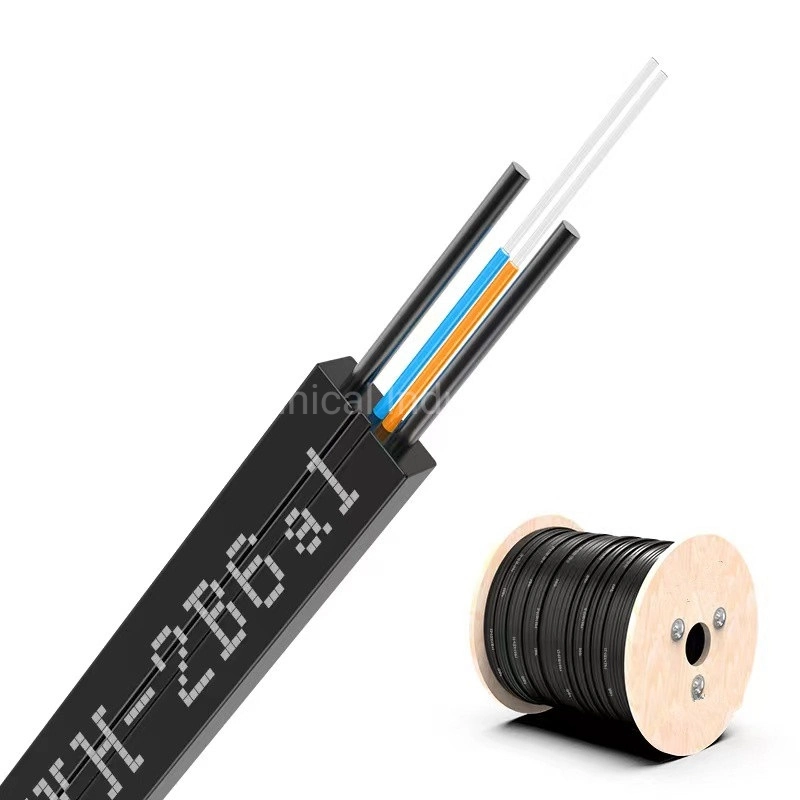

Optic Cable Outer sheathing Extrusion Production Line for Butterfly-shaped Fiber Optical cables^

HL-Technical specification

1.Production line application

It is used to produce butterfly-shaped optical cables, and the sheath material is LSZH low-smoke halogen-free fuel resistance.

2,Main technical index of production line

2.1 Geometric size of butterfly optical cable 2mm~2.5mm×3mm~6.5mm

2.2 Production line structure speed 200m/min

2.3 Production line speed 150m/min (Related to material)

2.4 Pay-off reel size Φ236×Φ25.4×108mm(25KM Reel)

Φ265×Φ25.4×180mm(50KM Reel)

2.5Fiber pay-off tension 0.5N~5N(Adjustable)

2.6Extrusion molding machine SJ65-25

2.7 Take-up tension 5N~30N(Adjustable)

2.8 Take-up reel size PN280/PN630

2.9 Production line direction To be determined

2.10 Production line color To be determined

2.11 Center height of production line 1000mm

3,Composition of production line

3.1 PN600-PN800 active swing arm type steel wire active pay-off rack 1set

3.2 Four-in-one automatic pay-off machine 1set

3.3 100kg drying and loading device 1set

3.4 SJ65-25 Extruder molding machine Length-diameter ratio 25:1, LSZH screw 1set

3.5 Stainless steel double-layer heat preservation and heating mobile sink 4m

3.6 Stainless steel double-layer heat preservation and heating water tank 6KW 1set

3.7 Stainless steel cold water tank 12m

4.1 PN600-PN800 swing arm type steel wire active pay-off rack

4.1.1 Structural features

The frame is a cabinet frame structure; it is driven by an AC frequency conversion controller, and a transmission mechanism composed of a frequency conversion motor and a reducer provides the unwinding power; the moving mechanism composed of a lifting motor and a reducer provides the unwinding power; the cylinder top is used for clamping and loosening The pay-off centering mechanism can effectively prevent the jitter caused by the wire obliquely pulled out; the pay-off tension control dance wheel is equipped with the air cylinder and precision pressure regulating valve to control the moving pulley. The moving pulley track adopts high-quality linear slide rails and sliders, and the equipment layout is reasonable and compact; the start and stop of the line are controlled by the local;

Electric control configuration: The main motor of the pay-off adopts a 7.5KW 4-pole AC variable frequency motor and a 5.5KW AC variable frequency controller; the lifting adopts a 1.1KW motor + reducer, and local control. With PID forward and reverse control.

4.1.2 Technical index

4.1.2.1 Wire reel size Ф630mm-Ф800mm

4.1.2.2 Steel wire reel shaft hole size Ф80mm

4.1.2.3 Wire pay-off tension 5N~50N(Adjustable)

4.1.2.4 Load-bearing 600kg

4.1.2.5 Pay-off structure speed max200m/min

4.2 Four-in-one automatic pay-off machine

4.2.1 Structural features

Two-way optical fiber pay-off: adopts active pay-off method; uses ultra-low friction cylinder and precision pressure regulating valve to control tension, dance wheel swing connection cam and analog output sensor distance change is converted into a control signal to control the pay-off, High control precision; frequency conversion drive; pay-off start and stop are controlled locally. With PID forward and reverse control.

Two-way FRP or steel wire pay-off: suitable for the largest PN430 reel, the maximum load is 50 kg, the drive mechanism composed of a motor and a reducer provides the pay-off power, the active pay-off method is adopted, and the 2.2KW AC frequency conversion motor and inverter control; Wire tension controller, the distance between the cam of the dance wheel and the analog output sensor is converted into a control signal to control the payout, with high control accuracy; the start and stop of the payout are controlled locally; it can meet the requirements of different speeds for steel wire reels under 35 kg The stable pay-off.

Optical fiber preheating and dehumidification adopts far-infrared light heating method to directly heat the entire optical fiber to make heating more effective; thermocouple controls the temperature, and the temperature can be set on the screen of the main cabinet.

4.2.2 Optical fiber pay-off technical indicators

4.2.3 Optical fiber diameter Φ0.254mm

4.2.4 Optical fiber tray size Φ236×Φ25.4×108mm(25KM Reel)

Φ265×Φ25.4×180mm(50KM Reel)

4.2.5 Optical fiber pay-off tension 0.4N~5N

4.2.6 Pay-off speed max200m/min

4.2.7 Axis runout accuracy ±0.05mm

4.2.8 FRP pay-off technical indicators

4.2.9 Pulley diameter Ф150mm;

4.2.10 Pay-off tension 5N~20N(Adjustable)

4.2.11 Pay-off speed max200m/min

4.2.12 Pay-off reel diameter

FRP Reel:Diameter Ф400mm* Width 290mm* Shaft Diameter 56mm,ID:200mm

Wire reel:Diameter Ф255mm* Width 165mm* Shaft Diameter 33mm,ID:120mm

(When using a disc with an inner diameter of 120mm, the production line speed is up to 75m/min)

Production line speed up to 100m/min

Diameter Ф400mm* Width 350mm* Shaft Diameter 55mm,ID:260mm

4.2.13 FRP reinforcement diameter Ф0.4mm~Ф1.0mm

Electronic control configuration: the main motor of the pay-off adopts 2.2KW 4-pole AC variable frequency motor, 2.2KW AC variable frequency controller; adopts 0~10V analog output sensor to control and drive; has PID forward and reverse control;

4.3 SJ65-25 Extruder molding machine

4.3.1 Structural features

Solid base, low-noise gear reducer; the screw is made of special bi-alloy nitrided steel; the screw length to diameter ratio is 25:1; the setting and display are embedded in the PC system, with interface PID and temperature correction functions, temperature control accuracy High; pressure sensor is installed on the screw barrel, and the actual value of the pressure of the screw barrel is displayed on the upper computer; it is equipped with a feeding and drying device, and the drying cylinder has a lower limit sensor. One set of molds for two specifications of leather cables.

4.3.2 Technical index

4.3.2.1 Length to diameter ratio 25:1, LSZH screw;

4.3.2.2 Main motor AC variable frequency motor, power 45KW;

4.3.2.3 100Kg hopper-type plastic dryer (with a feeding device, the motor is an inductive motor); the hopper has a lower limit sensor, and the barrel is equipped with a magnetic frame.

4.6.2.4 Screw speed 100rpm;

4.3.2.5 Maximum extrusion volume 150kg/h;

4.3.2.6 cooling method

The barrel is cooled by a fan (4-stage heating), and the head is heated in 3-stage Cooling water jacket in the blanking section (1 section of internal circulating water)

The screw has a hollow structure to control the water temperature or oil temperature of the internal circulation

4.3.2.7 Temperature control accuracy±1ºC.

4.3.2.8 Host center height 1000mm

4.3.2.9 High-precision extruder molding machine, spline connection.

4.3.2.10The connection between screwing system and extrusion head is 3-half structure

4.3.2.11The head adopts a built-in heating rod heating method.

4.3.2.12The extruder is equipped with 1 LSZH screw.

4.3.2.13Extruder with pressure detection sensor

If the pressure exceeds the set value 1, an alarm is issued, and the pressure exceeds the set value 2 to stop.

Temperature monitoring protection: The extruder cannot be turned on when the temperature is lower than the set temperature. During the production process, the temperature drop alarms and the speed decreases without stopping the machine (the current is too large at this time).

4.4 Mobile hot water tank 4M

4.4.1 Structural features

Made of SS304 material, thickness 2MM; double-layer insulation structure; with a V-shaped small water bucket, which can move forward and backward, with a movement amount of 400mm; it has an emergency water supplement function.

4.4.2 Technical index

4.4.2.1 Sink length 4m

4.5 Heating water tank

4.5.1 Structural features

Made of SS304 material; volume 0.3m3, water circulation system adopts 220V pipeline pump, water supply pipe with bypass device; stainless steel liquid level control device; heating setting and display embedded in industrial computer, with interface PID and temperature correction function, temperature control accuracy High; the lower limit of the water tank has an alarm signal, which is displayed on the industrial computer, and the heating is stopped when the water level is low.

4.5.2 Technical index

4.5.2.1 Volume 0.3m3

4.5.2.2 Circulating water volume 1.8m3/h

4.5.2.3 Temperature control accuracy when the water tank is not circulating ±1ºC

4.5.2.4 heating power 6KW

4.6 12m cold water tank

Made of SS304 material, the flow of the water head can be adjusted by the valve.

4.6 Single-wheel 630-wheel tractor (including cold water spray)

4.6.1 Structure

The imported 4KW Siemens servo motor drives the helical gear reducer to drive the Φ630 stainless steel traction wheel. The traction wheel is installed in a water tank welded by stainless steel 304 steel plate, connected with a 12m cold water tank, and the tank is sprayed with refrigerated water, equipped with a leak-proof folding door and a window. In addition, it is equipped with 4 Φ300 dividing line guide wheels, and the casing inside the casing is cooled. The maximum length is 12 meters, which ensures sufficient cooling of the cable at a line speed of 150m/min. When the speed is low, the pressure roller is pressed to prevent slipping. When the speed is above 50 meters, the pneumatic control pressure roller automatically disengages, which is convenient for high-speed operation.

4.6.2 Index

4.6.2.1 Traction wheel diameter: Φ630mm

4.6.2.2 Traction ≥ 250N

4.6.2.3 Traction speed: 20~200m/min

4.6.2.4 Temperature control range: Connect with refrigeration unit

4.7 Blow dryer

4.7.1 Structural features

Specially designed for tight-packed optical fibers, with an open-close structure and a wiper mode; users need to prepare their own air source.

4.7.2 Technical index

4.7.2.1 Open and close structure

4.8 Diameter

Made in China, Shanghai Gongjiu or Oule two-way diameter measuring instrument, the accuracy can reach ±0.001mm; it can communicate with the industrial computer in real time to realize the display of the product outer diameter on the industrial computer; it has the upper computer to set the nominal outer diameter value and positive and negative Tolerance value, and alarm if it exceeds the positive or negative value. The infrared rays of the detection butterfly cable are in a positive cross-shaped direction.

4.9 Inkjet printer

Adopt YMashi inkjet printer (user-selected)

4.10 Meter counting, ink-jet printing anti-shake guide, crimping stop and retreat integrated device

4.10.1Structure description:

There is a pair of meter wheels in front of the device, one meter wheel shaft is connected to the encoder with an elastic coupling, and there are 2 pairs of rollers with adjustable groove width at the front and back of the coding area to prevent the cable from shaking. The nozzle of the printer is in the area. Accurately spray characters inside, and there are up and down pressing and anti-retracting rubber rollers at the exit to prevent the cable from retreating when changing the reel. After the manual reel change is completed, the pressure roller will automatically loosen after the take-up machine runs for 10 seconds, reducing the rubber roller Wear.

4.11 Wire storage rack and take-up tension control guide wheel

4.11.1 Structural features

The wire storage structure is composed of multiple pulleys horizontally, the total length of the frame is 9m, the servo motor + planetary gear reducer controls the tension, and the absolute value encoder converts the moving position of the movable pulley into a control signal to control the wire take-up speed, with high control accuracy.

4.11.2 Technical indicators

4.11.2.1 pulley diameter Ф300mm (flat bottom);

4.11.2.2 The maximum length of storage line is 150m;

4.11.2.3 Take-up tension 5N~30N (adjustable).

4.12 Double reel winding machine

4.12.1 Structural features

It is composed of main frame, wire take-up unit, wire arranging unit and electrical system, etc., double-reel take-up, manual cutting, reel change, fixed-length light alarm, suitable for PN280~PN630 reel. The take-up adopts 2.2KW-6P AC variable frequency motor and inverter; adopts Panasonic AC servo motor to drive the cable, and the ball screw is used to automatically synchronize with the take-up speed. The cable pitch is continuously adjustable from 1mm to 7mm. The reversing switches all adopt electromagnetic proximity switches. The reversing position of the cable has a threaded fine-tuning mechanism, which is convenient for fine adjustment of the reversing position of the cable, and the axial positioning of the fast ferrule is adopted.

4.12.2 Technical Specifications

4.12.2.1 Applicable wire reel PN280mm~PN630mm

4.12.2.2 Take-up speed max200m/min

4.13 Electronic control system

4.13.1 The whole machine touch screen 15# (MCGS)--Siemens S7-1500 control.

4.13.2 The entire line of equipment can not only be linked synchronously, but also can be operated as a single machine.

4.13.3 Provide a control system to meet production, monitoring, and data management tasks. The control software includes process monitoring, alarm system, process menu system, various historical data, alarm records and report interfaces, system management, parameter settings; real-time display alarm monitoring , Historical data records, and production operations are all realized through the man-machine interface.

The displayed values are as follows:

Each pay-off rack displays: each pay-off rack (steel wire, optical fiber, ribbon fiber, FRP, etc.) components are ready or configured when the corresponding component color changes to green; when it is faulty or disconnected, the color changes to red.

Extruder display value: actual temperature value, screw barrel pressure value, screw speed, host current

lCooling system display: the actual temperature of the cold and hot water tank, the water supply display of the water pump (configuration color change to distinguish),

lDiameter display: display the actual outer diameter value

lInkjet printer display: ready or run configuration graphics color change

lTwo-wheel traction display: actual line speed display, main traction current value, actual meter display value

lWire storage rack display: the color changes when the wire is stored

lDual-disc take-up line display: configure the color change of graphics when preparing or running, configure the color change of the configuration graphics when the meter is preset, and give an alarm.

lEmergency stop display across the entire line: the color of the configuration graphic changes, and the point display of the emergency stop flashes.

lHistorical data curve and implementation curve display: production speed, screw speed, extruder current, outer diameter, screw pressure, traction speed; on the basis of the multiple interfaces provided by the above manufacturers, an additional interface in the form of cumulative alarm text: alarm time , The length of the alarm production product and the alarm content information are stored for 10 days;

lAt the same time, it can display the overall status of the production line.

4.13.4 The setting values are as follows:

lHost setting: manually increase or decrease screw speed value, screw barrel pressure upper limit, current upper limit, temperature setting value (with a separate interface to set the PID and temperature correction value of each heating zone), timing Heating setting (a cycle for 7 days) has a single linkage setting and operation

lExtrusion volume correction setting for each section of the extruder, setting value of host and traction speed-up ratio

lCooling system settings: two water tank temperature settings (with a separate interface to set the PID and temperature correction value of each heating zone), the water pump has a single linkage setting and operation

l Traction settings: line speed, preset meter, meter reset

Outer diameter test: setting of nominal value of outer diameter and setting of positive and negative tolerance; the actual value of the standard bar placed on the external meridian and the display value of the meridian on the PC interface have the function of setting the accuracy. The display error can be corrected. To ensure the accuracy of the foreign classics.

4.13.5 Alarm display:

lEach pay-off rack drives the alarm output, and the equipment stops;

lThe upper and lower limit of each pay-off dance wheel is alarmed, no matter which pay-off is disconnected, the machine can be manually switched to stop or slow down.

lThe host DC motor fault alarm; shutdown; the lower limit alarm of the material level of the drying barrel;

lAlarm for the lower limit of the water level of the hot and cold water tank;

l Traction fault alarm and shutdown

lTake-up drive alarm, cable failure alarm and non-stop

lAlarm for abnormal outer diameter

lInkjet printer abnormal alarm

For the above alarms, there are obvious alarm prompts on the display and a cumulative alarm text interface, and the alarm displays the meter length at the same time.

4.13.6 Monitoring interface:

lActual production line speed, actual host current, actual screw speed, actual screw barrel pressure, actual traction speed, external warp display, equipment running cumulative time per unit time (12 hours as a unit) curve or digital interface.

lThe above information needs to be stored for 10 days and can be viewed and printed at any time; the monitoring data can be copied out in a file package.

4.13.7 The number of input and output points reserved on the PLC:

l 4 digital inputs

l 4 output points;

l 2 analog inputs

l 2 output points

lLeave one path of fiber optic preheating device temperature feedback analog input, and one path of fiber optic preheating device opening and stopping digital output. And do the corresponding graphics on the configuration interface.

l Above, the remaining points are controlled accordingly on the host computer.

4.13.8 The electronic control of the extrusion unit and the tractor are controlled by their respective control cabinets.

4.13.9 There are audible and visual alarms for over-limit, and a special control cabinet is set up for the whole line of joint control and synchronization.

4.13.10 The cable number identification of the wiring in the electric cabinet is printed by the numbering machine and is clearly visible during the service life. The connecting line between the cabinet and the cabinet has a label and a wiring table. The electrical installation complies with IEC international standards.

4.13.11 The electric cabinet and its components shall have reasonable and effective ventilation and heat dissipation devices.

4.13.12 The production line is equipped with 3 emergency stop buttons (main cabinet, take-up stand, pay-off stand).

4.13.13 Regarding whether the supplier is configured or not, all the independent components included in the production line are equipped with corresponding independent power switches and wiring terminals to ensure that the power failure of the independent components does not affect the operation of other components.

4.13.14 Degree control system:

lThe temperature of each zone of the extruder is controlled, and the fluctuation is the set temperature ±2°C (at constant speed).

lWhen the hot water used in the first section of the water tank is heated, the temperature fluctuation is <±1ºC, and it has the function of over-temperature water supply.

The temperature is controlled by RKC meter, and a corresponding number of ammeters are installed on the panel of the electric control cabinet to display the working condition of the heater; the power control adopts Pioneer solid state relay.

lThe heating system of the extruder adopts a 380V voltage heater. The thermocouple, fan and other terminals are located on the side, and the height is not less than 500mm in the protective cover below the screw. Ensure enough space for the heater, thermocouple, and cooling fan. The wiring is not mixed, and each row of terminals is separated by a wire slot. The head heating adopts 220V,

lThe extruder starts the protection function. If the heating temperature does not reach the set protection temperature, the extruder cannot be started.

lIncrease environmental reference temperature all the way and preheat heating

4.13.15 Electrical components configuration:

lThe whole machine touch screen 15# (MCGS)--Siemens S7-1500 control.

lThe programmable controller uses Siemens S7-314 with a memory card.

lAll AC inverters use products, and optional inverters are configured according to the above specifications.

lThe frequency conversion motor adopts Pioneer frequency conversion motor or Siemens Bader frequency conversion motor;

lThe main power fast fuse adopts an integrated protective cover.

l Low-voltage electrical appliances adopt high-quality products from joint ventures (Siemens).

lThe wiring in the electrical cabinet, the power guide bar, the wire duct, and the terminal are selected from well-known domestic manufacturers.

lThe body is equipped with a pressure sensor, and the actual pressure value is displayed on the PC monitor.

lThe frequency converter adopts 2800 series, which is configured according to the above specified power.

lThe electrical cabinet is a standard electrical cabinet with length×width×height (800×600×2000).

lElectrical 2 cabinets: 1. Host computer and PLC cabinet, 2. Power supply cabinet (no matter whether it is provided by the supplier or not, all the independent components included in the production line are equipped with corresponding independent power switches and wiring terminals) heating cabinet (the main power fuse of the heater is always fast-acting) 3. Heating cabinet (the main power fuse of the heater is always fast-acting) 4. Host control cabinet (the main power fuse is fast-acting, and a special protective cover is added) 4. Traction control cabinet (the main power fuse is fast-acting, plus a special protective cover)

lAll solenoid valves are controlled by 24V DC.

lThe standard parts of the main mechanical equipment use NSK or Harbin shaft bearings. Other parts of the equipment also need to use reliable quality standard parts from well-known domestic manufacturers.

5,The information provided by the supplier to the buyer is as follows:

6, Equipment installation

HL-Technical specification

1.Production line application

It is used to produce butterfly-shaped optical cables, and the sheath material is LSZH low-smoke halogen-free fuel resistance.

2,Main technical index of production line

2.1 Geometric size of butterfly optical cable 2mm~2.5mm×3mm~6.5mm

2.2 Production line structure speed 200m/min

2.3 Production line speed 150m/min (Related to material)

2.4 Pay-off reel size Φ236×Φ25.4×108mm(25KM Reel)

Φ265×Φ25.4×180mm(50KM Reel)

2.5Fiber pay-off tension 0.5N~5N(Adjustable)

2.6Extrusion molding machine SJ65-25

2.7 Take-up tension 5N~30N(Adjustable)

2.8 Take-up reel size PN280/PN630

2.9 Production line direction To be determined

2.10 Production line color To be determined

2.11 Center height of production line 1000mm

3,Composition of production line

3.1 PN600-PN800 active swing arm type steel wire active pay-off rack 1set

3.2 Four-in-one automatic pay-off machine 1set

3.3 100kg drying and loading device 1set

3.4 SJ65-25 Extruder molding machine Length-diameter ratio 25:1, LSZH screw 1set

3.5 Stainless steel double-layer heat preservation and heating mobile sink 4m

3.6 Stainless steel double-layer heat preservation and heating water tank 6KW 1set

3.7 Stainless steel cold water tank 12m

3.8 Water bath type Φ630 wheel tractor (and cold water tank) 1set

3.9 Blow dryer 1set

3.10 Refrigeration unit 3HP 1set

3.11 Two-way diameter measuring instrument (Gongjiu) 1set

3.12 150m wire storage rack and tension controller 1set

3.13 Meter counting, ink-jet printing anti-shake guide, crimping stop and retreat integrated device 1set

3.14 Double reel take-up machine 1set

3.15 Electric control system 1set

3.9 Blow dryer 1set

3.10 Refrigeration unit 3HP 1set

3.11 Two-way diameter measuring instrument (Gongjiu) 1set

3.12 150m wire storage rack and tension controller 1set

3.13 Meter counting, ink-jet printing anti-shake guide, crimping stop and retreat integrated device 1set

3.14 Double reel take-up machine 1set

3.15 Electric control system 1set

4.1 PN600-PN800 swing arm type steel wire active pay-off rack

4.1.1 Structural features

The frame is a cabinet frame structure; it is driven by an AC frequency conversion controller, and a transmission mechanism composed of a frequency conversion motor and a reducer provides the unwinding power; the moving mechanism composed of a lifting motor and a reducer provides the unwinding power; the cylinder top is used for clamping and loosening The pay-off centering mechanism can effectively prevent the jitter caused by the wire obliquely pulled out; the pay-off tension control dance wheel is equipped with the air cylinder and precision pressure regulating valve to control the moving pulley. The moving pulley track adopts high-quality linear slide rails and sliders, and the equipment layout is reasonable and compact; the start and stop of the line are controlled by the local;

Electric control configuration: The main motor of the pay-off adopts a 7.5KW 4-pole AC variable frequency motor and a 5.5KW AC variable frequency controller; the lifting adopts a 1.1KW motor + reducer, and local control. With PID forward and reverse control.

4.1.2 Technical index

4.1.2.1 Wire reel size Ф630mm-Ф800mm

4.1.2.2 Steel wire reel shaft hole size Ф80mm

4.1.2.3 Wire pay-off tension 5N~50N(Adjustable)

4.1.2.4 Load-bearing 600kg

4.1.2.5 Pay-off structure speed max200m/min

4.2 Four-in-one automatic pay-off machine

4.2.1 Structural features

Two-way optical fiber pay-off: adopts active pay-off method; uses ultra-low friction cylinder and precision pressure regulating valve to control tension, dance wheel swing connection cam and analog output sensor distance change is converted into a control signal to control the pay-off, High control precision; frequency conversion drive; pay-off start and stop are controlled locally. With PID forward and reverse control.

Two-way FRP or steel wire pay-off: suitable for the largest PN430 reel, the maximum load is 50 kg, the drive mechanism composed of a motor and a reducer provides the pay-off power, the active pay-off method is adopted, and the 2.2KW AC frequency conversion motor and inverter control; Wire tension controller, the distance between the cam of the dance wheel and the analog output sensor is converted into a control signal to control the payout, with high control accuracy; the start and stop of the payout are controlled locally; it can meet the requirements of different speeds for steel wire reels under 35 kg The stable pay-off.

Optical fiber preheating and dehumidification adopts far-infrared light heating method to directly heat the entire optical fiber to make heating more effective; thermocouple controls the temperature, and the temperature can be set on the screen of the main cabinet.

4.2.2 Optical fiber pay-off technical indicators

4.2.3 Optical fiber diameter Φ0.254mm

4.2.4 Optical fiber tray size Φ236×Φ25.4×108mm(25KM Reel)

Φ265×Φ25.4×180mm(50KM Reel)

4.2.5 Optical fiber pay-off tension 0.4N~5N

4.2.6 Pay-off speed max200m/min

4.2.7 Axis runout accuracy ±0.05mm

4.2.8 FRP pay-off technical indicators

4.2.9 Pulley diameter Ф150mm;

4.2.10 Pay-off tension 5N~20N(Adjustable)

4.2.11 Pay-off speed max200m/min

4.2.12 Pay-off reel diameter

FRP Reel:Diameter Ф400mm* Width 290mm* Shaft Diameter 56mm,ID:200mm

Wire reel:Diameter Ф255mm* Width 165mm* Shaft Diameter 33mm,ID:120mm

(When using a disc with an inner diameter of 120mm, the production line speed is up to 75m/min)

Production line speed up to 100m/min

Diameter Ф400mm* Width 350mm* Shaft Diameter 55mm,ID:260mm

4.2.13 FRP reinforcement diameter Ф0.4mm~Ф1.0mm

Electronic control configuration: the main motor of the pay-off adopts 2.2KW 4-pole AC variable frequency motor, 2.2KW AC variable frequency controller; adopts 0~10V analog output sensor to control and drive; has PID forward and reverse control;

4.3 SJ65-25 Extruder molding machine

4.3.1 Structural features

Solid base, low-noise gear reducer; the screw is made of special bi-alloy nitrided steel; the screw length to diameter ratio is 25:1; the setting and display are embedded in the PC system, with interface PID and temperature correction functions, temperature control accuracy High; pressure sensor is installed on the screw barrel, and the actual value of the pressure of the screw barrel is displayed on the upper computer; it is equipped with a feeding and drying device, and the drying cylinder has a lower limit sensor. One set of molds for two specifications of leather cables.

4.3.2 Technical index

4.3.2.1 Length to diameter ratio 25:1, LSZH screw;

4.3.2.2 Main motor AC variable frequency motor, power 45KW;

4.3.2.3 100Kg hopper-type plastic dryer (with a feeding device, the motor is an inductive motor); the hopper has a lower limit sensor, and the barrel is equipped with a magnetic frame.

4.6.2.4 Screw speed 100rpm;

4.3.2.5 Maximum extrusion volume 150kg/h;

4.3.2.6 cooling method

The barrel is cooled by a fan (4-stage heating), and the head is heated in 3-stage Cooling water jacket in the blanking section (1 section of internal circulating water)

The screw has a hollow structure to control the water temperature or oil temperature of the internal circulation

4.3.2.7 Temperature control accuracy±1ºC.

4.3.2.8 Host center height 1000mm

4.3.2.9 High-precision extruder molding machine, spline connection.

4.3.2.10The connection between screwing system and extrusion head is 3-half structure

4.3.2.11The head adopts a built-in heating rod heating method.

4.3.2.12The extruder is equipped with 1 LSZH screw.

4.3.2.13Extruder with pressure detection sensor

If the pressure exceeds the set value 1, an alarm is issued, and the pressure exceeds the set value 2 to stop.

Temperature monitoring protection: The extruder cannot be turned on when the temperature is lower than the set temperature. During the production process, the temperature drop alarms and the speed decreases without stopping the machine (the current is too large at this time).

4.4 Mobile hot water tank 4M

4.4.1 Structural features

Made of SS304 material, thickness 2MM; double-layer insulation structure; with a V-shaped small water bucket, which can move forward and backward, with a movement amount of 400mm; it has an emergency water supplement function.

4.4.2 Technical index

4.4.2.1 Sink length 4m

4.5 Heating water tank

4.5.1 Structural features

Made of SS304 material; volume 0.3m3, water circulation system adopts 220V pipeline pump, water supply pipe with bypass device; stainless steel liquid level control device; heating setting and display embedded in industrial computer, with interface PID and temperature correction function, temperature control accuracy High; the lower limit of the water tank has an alarm signal, which is displayed on the industrial computer, and the heating is stopped when the water level is low.

4.5.2 Technical index

4.5.2.1 Volume 0.3m3

4.5.2.2 Circulating water volume 1.8m3/h

4.5.2.3 Temperature control accuracy when the water tank is not circulating ±1ºC

4.5.2.4 heating power 6KW

4.6 12m cold water tank

Made of SS304 material, the flow of the water head can be adjusted by the valve.

4.6 Single-wheel 630-wheel tractor (including cold water spray)

4.6.1 Structure

The imported 4KW Siemens servo motor drives the helical gear reducer to drive the Φ630 stainless steel traction wheel. The traction wheel is installed in a water tank welded by stainless steel 304 steel plate, connected with a 12m cold water tank, and the tank is sprayed with refrigerated water, equipped with a leak-proof folding door and a window. In addition, it is equipped with 4 Φ300 dividing line guide wheels, and the casing inside the casing is cooled. The maximum length is 12 meters, which ensures sufficient cooling of the cable at a line speed of 150m/min. When the speed is low, the pressure roller is pressed to prevent slipping. When the speed is above 50 meters, the pneumatic control pressure roller automatically disengages, which is convenient for high-speed operation.

4.6.2 Index

4.6.2.1 Traction wheel diameter: Φ630mm

4.6.2.2 Traction ≥ 250N

4.6.2.3 Traction speed: 20~200m/min

4.6.2.4 Temperature control range: Connect with refrigeration unit

4.7 Blow dryer

4.7.1 Structural features

Specially designed for tight-packed optical fibers, with an open-close structure and a wiper mode; users need to prepare their own air source.

4.7.2 Technical index

4.7.2.1 Open and close structure

4.8 Diameter

Made in China, Shanghai Gongjiu or Oule two-way diameter measuring instrument, the accuracy can reach ±0.001mm; it can communicate with the industrial computer in real time to realize the display of the product outer diameter on the industrial computer; it has the upper computer to set the nominal outer diameter value and positive and negative Tolerance value, and alarm if it exceeds the positive or negative value. The infrared rays of the detection butterfly cable are in a positive cross-shaped direction.

4.9 Inkjet printer

Adopt YMashi inkjet printer (user-selected)

4.10 Meter counting, ink-jet printing anti-shake guide, crimping stop and retreat integrated device

4.10.1Structure description:

There is a pair of meter wheels in front of the device, one meter wheel shaft is connected to the encoder with an elastic coupling, and there are 2 pairs of rollers with adjustable groove width at the front and back of the coding area to prevent the cable from shaking. The nozzle of the printer is in the area. Accurately spray characters inside, and there are up and down pressing and anti-retracting rubber rollers at the exit to prevent the cable from retreating when changing the reel. After the manual reel change is completed, the pressure roller will automatically loosen after the take-up machine runs for 10 seconds, reducing the rubber roller Wear.

4.11 Wire storage rack and take-up tension control guide wheel

4.11.1 Structural features

The wire storage structure is composed of multiple pulleys horizontally, the total length of the frame is 9m, the servo motor + planetary gear reducer controls the tension, and the absolute value encoder converts the moving position of the movable pulley into a control signal to control the wire take-up speed, with high control accuracy.

4.11.2 Technical indicators

4.11.2.1 pulley diameter Ф300mm (flat bottom);

4.11.2.2 The maximum length of storage line is 150m;

4.11.2.3 Take-up tension 5N~30N (adjustable).

4.12 Double reel winding machine

4.12.1 Structural features

It is composed of main frame, wire take-up unit, wire arranging unit and electrical system, etc., double-reel take-up, manual cutting, reel change, fixed-length light alarm, suitable for PN280~PN630 reel. The take-up adopts 2.2KW-6P AC variable frequency motor and inverter; adopts Panasonic AC servo motor to drive the cable, and the ball screw is used to automatically synchronize with the take-up speed. The cable pitch is continuously adjustable from 1mm to 7mm. The reversing switches all adopt electromagnetic proximity switches. The reversing position of the cable has a threaded fine-tuning mechanism, which is convenient for fine adjustment of the reversing position of the cable, and the axial positioning of the fast ferrule is adopted.

4.12.2 Technical Specifications

4.12.2.1 Applicable wire reel PN280mm~PN630mm

4.12.2.2 Take-up speed max200m/min

4.13 Electronic control system

4.13.1 The whole machine touch screen 15# (MCGS)--Siemens S7-1500 control.

4.13.2 The entire line of equipment can not only be linked synchronously, but also can be operated as a single machine.

4.13.3 Provide a control system to meet production, monitoring, and data management tasks. The control software includes process monitoring, alarm system, process menu system, various historical data, alarm records and report interfaces, system management, parameter settings; real-time display alarm monitoring , Historical data records, and production operations are all realized through the man-machine interface.

The displayed values are as follows:

Each pay-off rack displays: each pay-off rack (steel wire, optical fiber, ribbon fiber, FRP, etc.) components are ready or configured when the corresponding component color changes to green; when it is faulty or disconnected, the color changes to red.

Extruder display value: actual temperature value, screw barrel pressure value, screw speed, host current

lCooling system display: the actual temperature of the cold and hot water tank, the water supply display of the water pump (configuration color change to distinguish),

lDiameter display: display the actual outer diameter value

lInkjet printer display: ready or run configuration graphics color change

lTwo-wheel traction display: actual line speed display, main traction current value, actual meter display value

lWire storage rack display: the color changes when the wire is stored

lDual-disc take-up line display: configure the color change of graphics when preparing or running, configure the color change of the configuration graphics when the meter is preset, and give an alarm.

lEmergency stop display across the entire line: the color of the configuration graphic changes, and the point display of the emergency stop flashes.

lHistorical data curve and implementation curve display: production speed, screw speed, extruder current, outer diameter, screw pressure, traction speed; on the basis of the multiple interfaces provided by the above manufacturers, an additional interface in the form of cumulative alarm text: alarm time , The length of the alarm production product and the alarm content information are stored for 10 days;

lAt the same time, it can display the overall status of the production line.

4.13.4 The setting values are as follows:

lHost setting: manually increase or decrease screw speed value, screw barrel pressure upper limit, current upper limit, temperature setting value (with a separate interface to set the PID and temperature correction value of each heating zone), timing Heating setting (a cycle for 7 days) has a single linkage setting and operation

lExtrusion volume correction setting for each section of the extruder, setting value of host and traction speed-up ratio

lCooling system settings: two water tank temperature settings (with a separate interface to set the PID and temperature correction value of each heating zone), the water pump has a single linkage setting and operation

l Traction settings: line speed, preset meter, meter reset

Outer diameter test: setting of nominal value of outer diameter and setting of positive and negative tolerance; the actual value of the standard bar placed on the external meridian and the display value of the meridian on the PC interface have the function of setting the accuracy. The display error can be corrected. To ensure the accuracy of the foreign classics.

4.13.5 Alarm display:

lEach pay-off rack drives the alarm output, and the equipment stops;

lThe upper and lower limit of each pay-off dance wheel is alarmed, no matter which pay-off is disconnected, the machine can be manually switched to stop or slow down.

lThe host DC motor fault alarm; shutdown; the lower limit alarm of the material level of the drying barrel;

lAlarm for the lower limit of the water level of the hot and cold water tank;

l Traction fault alarm and shutdown

lTake-up drive alarm, cable failure alarm and non-stop

lAlarm for abnormal outer diameter

lInkjet printer abnormal alarm

For the above alarms, there are obvious alarm prompts on the display and a cumulative alarm text interface, and the alarm displays the meter length at the same time.

4.13.6 Monitoring interface:

lActual production line speed, actual host current, actual screw speed, actual screw barrel pressure, actual traction speed, external warp display, equipment running cumulative time per unit time (12 hours as a unit) curve or digital interface.

lThe above information needs to be stored for 10 days and can be viewed and printed at any time; the monitoring data can be copied out in a file package.

4.13.7 The number of input and output points reserved on the PLC:

l 4 digital inputs

l 4 output points;

l 2 analog inputs

l 2 output points

lLeave one path of fiber optic preheating device temperature feedback analog input, and one path of fiber optic preheating device opening and stopping digital output. And do the corresponding graphics on the configuration interface.

l Above, the remaining points are controlled accordingly on the host computer.

4.13.8 The electronic control of the extrusion unit and the tractor are controlled by their respective control cabinets.

4.13.9 There are audible and visual alarms for over-limit, and a special control cabinet is set up for the whole line of joint control and synchronization.

4.13.10 The cable number identification of the wiring in the electric cabinet is printed by the numbering machine and is clearly visible during the service life. The connecting line between the cabinet and the cabinet has a label and a wiring table. The electrical installation complies with IEC international standards.

4.13.11 The electric cabinet and its components shall have reasonable and effective ventilation and heat dissipation devices.

4.13.12 The production line is equipped with 3 emergency stop buttons (main cabinet, take-up stand, pay-off stand).

4.13.13 Regarding whether the supplier is configured or not, all the independent components included in the production line are equipped with corresponding independent power switches and wiring terminals to ensure that the power failure of the independent components does not affect the operation of other components.

4.13.14 Degree control system:

lThe temperature of each zone of the extruder is controlled, and the fluctuation is the set temperature ±2°C (at constant speed).

lWhen the hot water used in the first section of the water tank is heated, the temperature fluctuation is <±1ºC, and it has the function of over-temperature water supply.

The temperature is controlled by RKC meter, and a corresponding number of ammeters are installed on the panel of the electric control cabinet to display the working condition of the heater; the power control adopts Pioneer solid state relay.

lThe heating system of the extruder adopts a 380V voltage heater. The thermocouple, fan and other terminals are located on the side, and the height is not less than 500mm in the protective cover below the screw. Ensure enough space for the heater, thermocouple, and cooling fan. The wiring is not mixed, and each row of terminals is separated by a wire slot. The head heating adopts 220V,

lThe extruder starts the protection function. If the heating temperature does not reach the set protection temperature, the extruder cannot be started.

lIncrease environmental reference temperature all the way and preheat heating

4.13.15 Electrical components configuration:

lThe whole machine touch screen 15# (MCGS)--Siemens S7-1500 control.

lThe programmable controller uses Siemens S7-314 with a memory card.

lAll AC inverters use products, and optional inverters are configured according to the above specifications.

lThe frequency conversion motor adopts Pioneer frequency conversion motor or Siemens Bader frequency conversion motor;

lThe main power fast fuse adopts an integrated protective cover.

l Low-voltage electrical appliances adopt high-quality products from joint ventures (Siemens).

lThe wiring in the electrical cabinet, the power guide bar, the wire duct, and the terminal are selected from well-known domestic manufacturers.

lThe body is equipped with a pressure sensor, and the actual pressure value is displayed on the PC monitor.

lThe frequency converter adopts 2800 series, which is configured according to the above specified power.

lThe electrical cabinet is a standard electrical cabinet with length×width×height (800×600×2000).

lElectrical 2 cabinets: 1. Host computer and PLC cabinet, 2. Power supply cabinet (no matter whether it is provided by the supplier or not, all the independent components included in the production line are equipped with corresponding independent power switches and wiring terminals) heating cabinet (the main power fuse of the heater is always fast-acting) 3. Heating cabinet (the main power fuse of the heater is always fast-acting) 4. Host control cabinet (the main power fuse is fast-acting, and a special protective cover is added) 4. Traction control cabinet (the main power fuse is fast-acting, plus a special protective cover)

lAll solenoid valves are controlled by 24V DC.

lThe standard parts of the main mechanical equipment use NSK or Harbin shaft bearings. Other parts of the equipment also need to use reliable quality standard parts from well-known domestic manufacturers.

5,The information provided by the supplier to the buyer is as follows:

- lEquipment manual

- lProduct qualification certificate

- lQuality Assurance

- lEquipment outline layout drawing and installation foundation drawing (delivered within one week after the contract takes effect)

- lEquipment installation wiring diagram (including water, electricity, gas, etc.) (delivered within one week after the contract takes effect)

- lElectrical principles and wiring diagrams of all electrical equipment (the drawings are consistent with the actual object, and the actual wiring is consistent with the wire number)

- l Equipment packing list

- lProvide Chinese manuals for equipment and electrical components (DC speed regulators, inverters, etc.).

- lMechanical assembly drawing of main equipment

- lDetailed schematic diagram

- lAccessories list (indicate key parts, such as all belt models, drawings of vulnerable mechanical parts)

- lBearing-cable table

- lInstructions and certificates of purchased parts

- lLine type, diameter, and length of the cable used for the external connection of the equipment (delivered at the initial inspection of the equipment)

6, Equipment installation

- lAfter the equipment is manufactured, it shall be installed and debugged in the supplier's factory (single machine test operation is possible), and the buyer will be notified to the supplier's factory and preliminary acceptance shall be carried out according to the process operation, equipment maintenance, structural rationality and safety.

- lWhen the equipment arrives at the buyer's factory, two machines and two electric personnel are required to conduct on-site debugging until the equipment enters the primary management assessment period.

- lThe installation, installation and on-site equipment of the equipment at the buyer's factory shall be completed by the buyer according to the drawings provided by the supplier.

- lThe on-site commissioning of the equipment is carried out by the supplier's technicians.

7, Equipment acceptance

- lHardware (mechanical hardware and electronic control hardware), software (electronic control software) meet the technical requirements and specifications.

- lEach stand-alone operation is balanced, no vibration, abnormal noise, and normal temperature rise.

- lThere is no dripping or dripping in all parts.

- lThe whole machine is balanced and stable.

- lTrial products and requirements:

- l If the relevant technical requirements are not involved, the original technical specifications shall be implemented.

- l Accepted products meet the relevant technical requirements of YDT 1997-2009 standard optical cable.