Basic Info.

Model NO.

T-OF001-G. 657. A2

Core

Single Core

Certification

RoHS, CE, ISO9001

Brand

Toem

Sheath Material

Fibre Optic

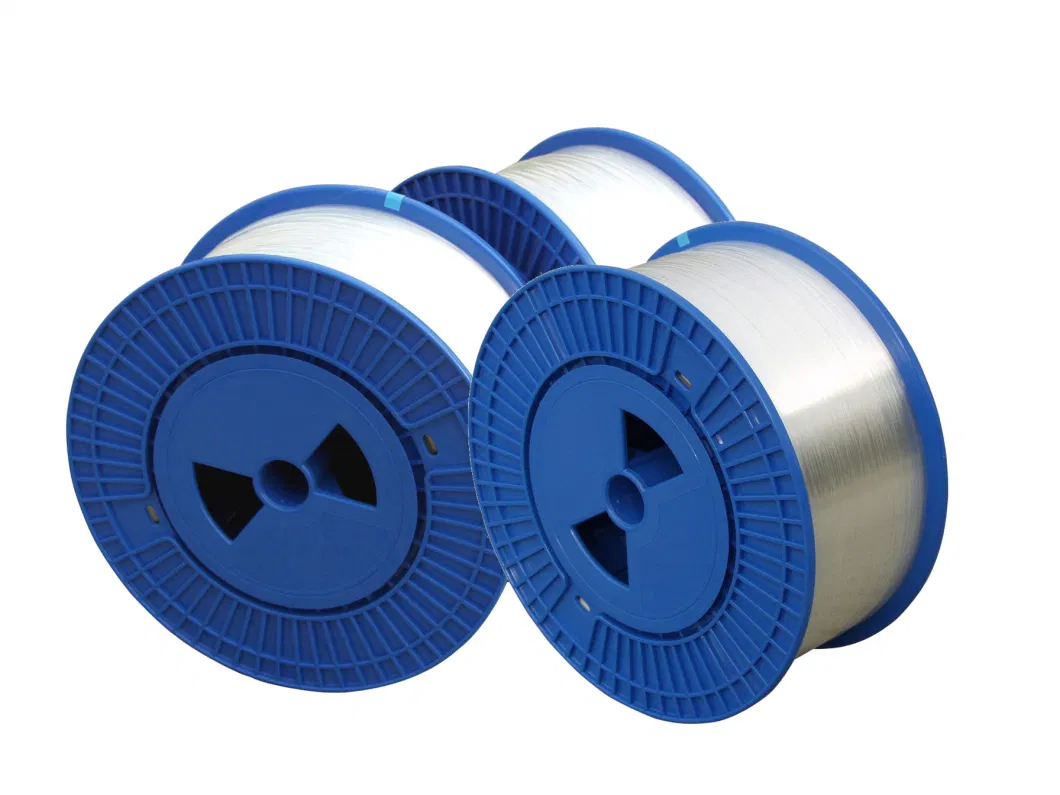

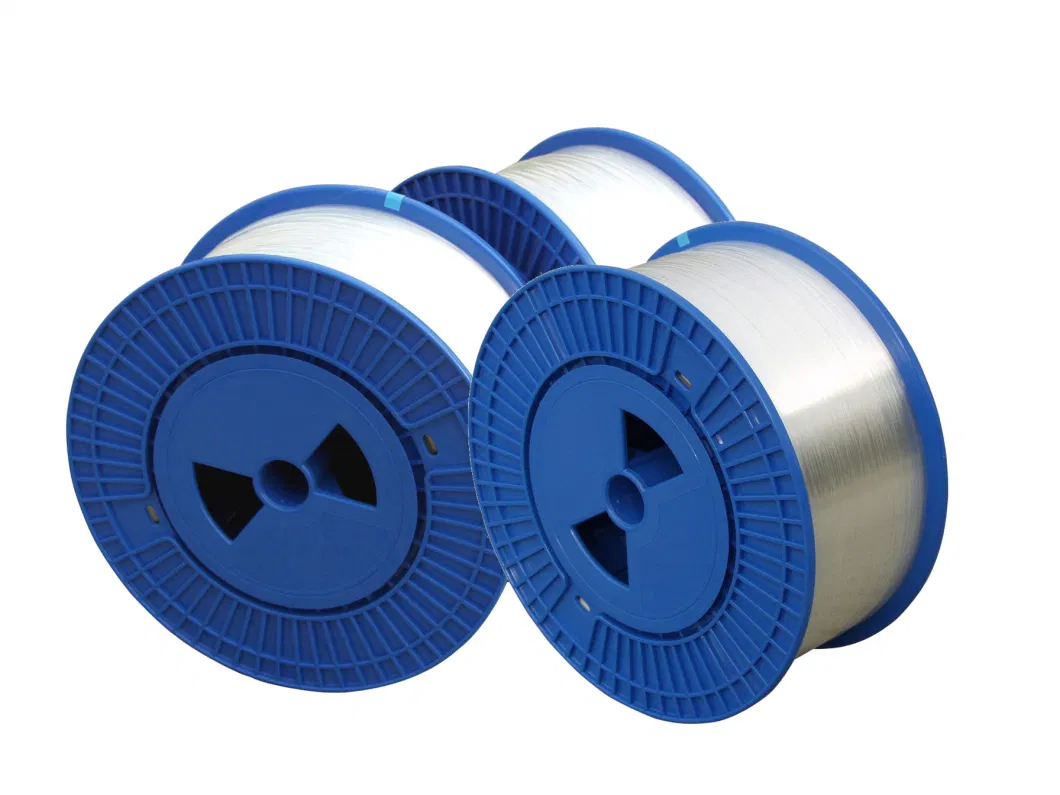

Transport Package

Plastic Drum

Specification

Single-mode Fiber

Origin

China

HS Code

9001100001

Product Description

AOF Bend-insensitive Single-mode Fiber

It encompasses all the features of Non-Dispersion Shift Single-mode Fiber and even does better in the aspect of bending property, particularly adapt the transmission system across the entire 1260nm to 1625nm wavelength spectrum. The AOF Fiber performs low bending additional loss in the long wavelength region. Even in the 1625nm wavelength window, the fibers only have a low additional loss equals to 0.8dB with a bending radius being 7.5mm.The Fiber can be used in all cable constructions, especially tight buffered cable which is the key of Fiber-To-The-Home and Fiber-To-The-Mansion

Features

The fiber complies with or exceeds the ITU-T Recommendation G.652.D and G.657.A1, the IEC International Standard 60793-2-50 type B.1.3 Optical Fiber Specification.

The fiber is manufactured using the advanced VAD process. Because of the advantages of the process, AOF fiber shows extremely refined refractive index profile control, excellent geometrical performance, low attenuation, etc.

What We Have In The Field Of Telecom Optical & Electric Cable :

1>Mature and Efficient Supply Chain System And Rich Industrial Resources

2>Complete Materials Demand Solutions For Cable Manufacturing And Technical Services

3>Overall Solutions And Customized Services In Factory Design, Equipment Configuration, Product Development And Rawmaterial Supply

*Quotation Varies According To Customer's Requirements And Quantity Of Products

It encompasses all the features of Non-Dispersion Shift Single-mode Fiber and even does better in the aspect of bending property, particularly adapt the transmission system across the entire 1260nm to 1625nm wavelength spectrum. The AOF Fiber performs low bending additional loss in the long wavelength region. Even in the 1625nm wavelength window, the fibers only have a low additional loss equals to 0.8dB with a bending radius being 7.5mm.The Fiber can be used in all cable constructions, especially tight buffered cable which is the key of Fiber-To-The-Home and Fiber-To-The-Mansion

Features

The fiber complies with or exceeds the ITU-T Recommendation G.652.D and G.657.A1, the IEC International Standard 60793-2-50 type B.1.3 Optical Fiber Specification.

The fiber is manufactured using the advanced VAD process. Because of the advantages of the process, AOF fiber shows extremely refined refractive index profile control, excellent geometrical performance, low attenuation, etc.

- Designed for operation over the 1260nm to 1625nm wavelength spectrum, completely low attenuation in the 1383 nm region;

- Excellent bending property adapting special occasions which require bending radius;

- Being compatible with existing G.652D Fiber;

- Accurate geometrical parameters that insure low splicing loss and high splicing efficiency;

- Excellent PMD factor supporting high-speed and distance upgrades.

| Characteristics Conditions Units Specified Values |

| Optical Characteristics |

| Attenuation |

| 1310nm dB/km ≤0.35 |

| 1550nm dB/km ≤0.21 |

| 1625nm dB/km ≤0.24 |

| 1383nm dB/km ≤0.32 |

| Attenuation vs. Wavelength |

| 1310nm 1285-1330nm dB/km ≤0.04 |

| 1550nm 1525-1575nm dB/km ≤0.03 |

| 1550nm 1480-1580nm dB/km ≤0.05 |

| Dispersion coefficients |

| 1288-1339nm ps/(nm·km) ≥-3.5,≤3.5 |

| 1371-1360nm ps/(nm·km) ≥-5.3,≤5.3 |

| 1480-1580nm ps/(nm·km) ≤20 |

| 1550nm ps/(nm·km) ≤18 |

| 1625nm ps/(nm·km) ≤22 |

| Zero dispersion wavelength nm 1300-1322 |

| Zero dispersion slope ps/(nm2·km) ≤0.091 |

| Zero dispersion slope typical value ps/(nm2·km) 0.086 |

| PMD: |

| Maximum Individual Fiber ps/√¯km 0.2 |

| Link Design Value(M=20,Q=0.01%) ps/√¯km 0.1 |

| Typical Value ps/√¯km 0.04 |

| Cable cutoff wavelengthλcc nm ≤1260 |

| Fiber cutoff wavelengthλc nm 1150-1330 |

| Mode field diameter(MFD) 1310nm μm 8.7±0.4 |

| 1550nm μm 9.6±0.5 |

| Effective group index of refraction |

| 1310nm 1.4672 |

| 1550nm 1.4683 |

| Attenuation Discontinuity 1310nm dB/km ≤0.05 |

| 1550nm dB/km ≤0.05 |

| Attenuation Bidirectional Measurement |

| 1310nm dB/km ≤0.05 |

| 1550nm dB/km ≤0.05 |

| Attenuation Uniformity 1310nm dB/km ≤0.05 |

| 1550nm dB/km ≤0.05 |

| Welding Loss |

| Average Value 1310nm,1550nm dB ≤0.05 |

| Maximum Value 1310nm,1550nm dB ≤0.1 |

| Geometrical Characteristics |

| Cladding diameter μm 125±0.7 |

| Cladding non-circularity % ≤0.8 |

| Core-cladding concentricity error μm ≤0.5 |

| Coating diameter μm 245±5 |

| Cladding-coating concentricity μm ≤12 |

| Coating non-circularity % ≤3.0 |

| Curl m ≥4 |

| Environmental Characteristics (1310nm,1550nm,1625nm) |

| Temperature Dependence -60ºC ~+85ºC dB/km ≤0.05 |

| Damp heat dependence 85ºC,RH85%,30days dB/km ≤0.05 |

| Water Immersion 23ºC,30days dB/km ≤0.05 |

| Heat Aging 85ºC,30days dB/km ≤0.05 |

| Mechanical Specification |

| Proof test % ≥1.02 |

| N ≥9.1 |

| Gpa ≥7.04 |

| Coating strip force Peak force N 1.3-8.9 |

| Typical average force N 1.9 |

| Tensile Strength Weibull Probability 50% Mpa ≥4000 |

| Weibull Probability 15% Mpa ≥3050 |

| Dynamic stress corrosion susceptibility parameter Nd ≥20 |

| Macro-bend Loss |

| 10 turn around a mandrel of 15mm radius |

| 1550nm dB ≤0.03 |

| 1625nm dB ≤0.1 |

| 1 turn around a mandrel of 10mm radius |

| 1550nm dB ≤0.1 |

| 1625nm dB ≤0.2 |

| 1 turn around a mandrel of 7.5mm radius |

| 1550nm dB ≤0.4 |

| 1625nm dB ≤0.8 |

What We Have In The Field Of Telecom Optical & Electric Cable :

1>Mature and Efficient Supply Chain System And Rich Industrial Resources

2>Complete Materials Demand Solutions For Cable Manufacturing And Technical Services

3>Overall Solutions And Customized Services In Factory Design, Equipment Configuration, Product Development And Rawmaterial Supply

*Quotation Varies According To Customer's Requirements And Quantity Of Products